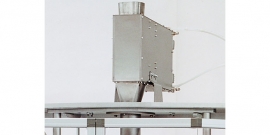

The VERTICAL packaging machine MC implements the most modern technology of the servo-controlled movements. Designed for high production speeds, with the welding system of the "long-term continuous translating motion" type to meet any requirement of the product, and the format required by the customer.

Ease of use, operator safety, high quality and trade materials, suitable for high production with an excellent quality-price ratio.

Use of a touch-screen controller and ability to create production recipes in a simple and intuitive manner.

The version of the continuous motion packaging machine MC is divided into two versions:

MC/05 Designed for High Speed for Flow-Pack packages with Box Motion.

MC/11 Designed for High Speed for Flow-Pack/Square bottom/4 welds packages handled by a movable trolley

TECHNICAL DATA OF MC/05 :

Welding by hot bar for any type of sealable film.

Suitable for packaging any type of product in pillow bags (Flow-Pack).

It can be equipped with devices for labels and print, automatic coil change.

Groups of special execution pliers for realization through Euroforo die.

Electrical panel integrated into the machine to save space.

Max. film width 520mm (for M92/520)

Flow-Pack speed: up to 130 packages per minute.

TECHNICAL DATA OF MC/11 :

Welding by hot bar for any type of sealable film.

Suitable for packaging any type of product in pillow bags (Flow-Pack),

square bottom bags, bags with four side welds of the stabilopack type.

It can be equipped with devices for labels and print, automatic coil change.

Groups of special execution pliers for realization through Euroforo die.

Electrical panel integrated into the machine to save space.

Max. film width 520 mm (for M92/520)

Max. film width 700mm (for M92/700)

Square bottom and four welds speed: up to 70 packages per minute.